The use of frequency converters has been going through more than half a century, and their main advantage is that they reduce electricity consumption. With the development of Industry 4.0, it has become the "black technology" in this industrial revolution. Its role has shifted from a pure power processor to an intelligent component in automation systems, and it can be used as an intelligent sensor, becoming a natural choice for implementing condition monitoring.

Powerful control functions continuously optimize water industry applications

The frequency converter used for power electrical conversion has been in use for over half a century. Today, over 20% of motors are driven by frequency converters, which can reduce energy consumption; On the other hand, it has excellent performance in process control (maintaining constant water pressure to avoid leakage caused by high pressure), avoiding water hammer, and optimizing water well extraction in the water industry applications.

Since the introduction of microprocessors for control, frequency converters have added other functions in addition to their original power processing functions. For example, in water industry applications, it is possible to control the operation of pumps, as well as perform multi pump control and bypass certain frequencies to avoid resonance. In industrial applications, frequency converters also integrate motion control and are taking over more and more PLC functions.

Industry 4.0, which has information and interconnection functions, has taken a new leap forward in frequency converters based on these additional functions. So we started using it as intelligent and networked sensors.

Industry 4.0 in Motor and Frequency Converter Systems

Industry 4.0 is a general term that can also be understood as the Fourth Industrial Revolution, characterized by the interconnection of all things, following the previous three Industrial Revolutions (First Industrial Revolution - Mechanization, Second Industrial Revolution - Electrification, Third Industrial Revolution - Automation)

We can define it as "utilizing all digital possibilities in the entire value chain to achieve intelligent interconnection of people, devices, and systems".

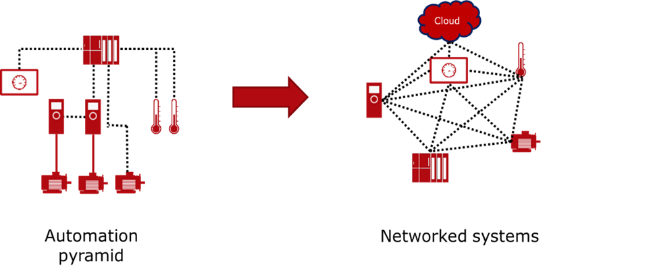

This trend has brought about an impact on the migration of motor systems from the so-called "automation pyramid" to interconnected systems, which means that various parts of the system are interconnected, such as motors, frequency converters, sensors, and controllers, and they are connected to the cloud for storage, processing, data analysis, and decision-making (see Figure 1, right).

Figure 1: Industry 4.0 signifies the transition from an automated pyramid to a networked system

The process of migrating the "automation pyramid" to interconnected systems also gives frequency converters the powerful ability to become "sensors". In addition, frequency converters need to collect more information and data to fully utilize the powerful functions of sensors.

Frequency converter becomes an intelligent sensor for monitoring working conditions

In frequency converter applications, built-in microprocessors and bus communication options allow for the connection of more sensors (such as vibration and pressure sensors) in addition to current and voltage sensors. This also opens up new application opportunities for it. Therefore, frequency converters can be used as intelligent sensors for condition monitoring (Figure 2). These information data can provide users with various applications, such as system optimization, energy efficiency optimization, and condition based maintenance.