Norwegian fjords have entered a zero emission future era

As the world's first fully electric carbon fiber ship, the "Fjord Future" represents the latest standard for environmentally responsible passenger ships. The development of this electric catamaran is consistent with the company's goal of minimizing environmental impact on Norwegian fjords while maximizing the natural beauty experience for passengers. The route is located within the original N Å r ø yfjord and belongs to the UNESCO World Heritage Park.

In 2018, the Norwegian parliament passed a resolution to make its iconic fjord a zero emission zone as soon as possible and by 2026 at the latest. This sets a deadline for ship operators in the fjord to eliminate pollution emissions from their ships, and the "Fjord Future" will achieve this goal eight years ahead of schedule. Our mission is to protect our fragile environment while providing passengers with the absolute best experience, "explains Rolf Sandvik, CEO of The Fjords. The ship won the "Ship of the Year" award at the Hamburg SMM 2018 Marine Trade Expo, recognizing the achievements made in achieving zero emissions targets.

Protecting the original environment

This ship has proven that while maximizing the traveler's experience, it can ensure minimal impact on the magnificent fjord environment. Panoramic windows and mountain shaped outdoor walkways provide passengers with spectacular scenery and unparalleled natural beauty experiences.

Innovative design for pure performance

Optimizing energy efficiency is a key strategy to ensure the survival ability of ships and reduce their environmental impact. Therefore, the "Fjord Future" adopts high-tech solutions from various fields to achieve the lowest possible energy consumption. The lightweight carbon laminates of the hull and superstructure can ensure a weight reduction of approximately half compared to traditional materials.

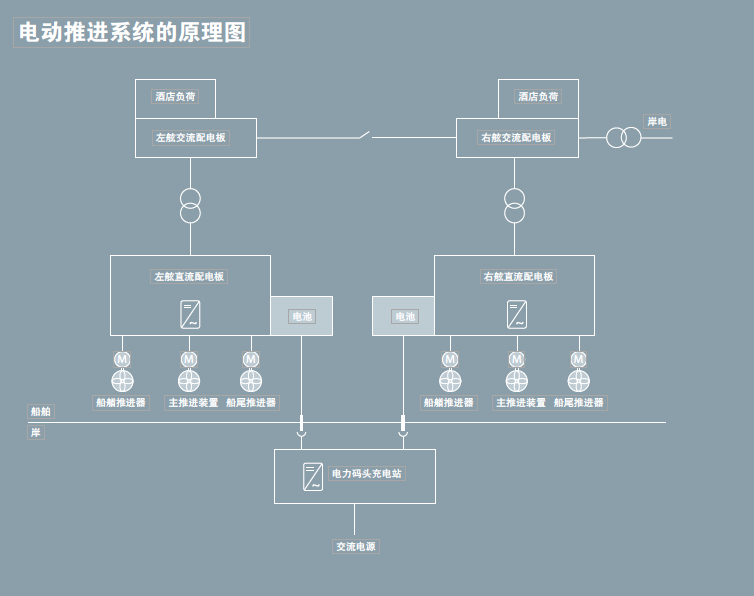

The advanced catamaran design also reduces the damage caused by accumulated waves and erosion on the exposed coast of narrow fjords. Its innovative propulsion system is battery powered, and the ship also integrates an upgraded IT system, providing convenience for digital passengers.

The Westcon Power&Automation solution is integrated throughout the entire ship, continuously performing control, tuning, and optimization of performance in the background. Several Westcon products use Danfoss components including inverters, including those used for main propulsion, auxiliary power grids, and charging devices. These inverters ensure reliable operation while reducing maintenance frequency to an absolute minimum. The key is the two electric motors driven by battery packs, which are the main source of power for the ship.

The battery pack drives two electric motors. The battery pack consists of 8 sets of batteries, each with 17 battery modules, with a total power capacity of 1.8 MWh. After charging, the ship can run at a speed of 11 knots for more than two hours. This performance optimization is not accidental: the Danfoss MBT sensor connected to the fan ventilation control ensures that the battery room is always at the appropriate temperature.

Propulsion devices without fossil fuels

While steadily moving forward, eliminate pollutants and carbon emissions brought by ship navigation, and reduce noise. The electric propulsion system enables ships to achieve zero emission navigation at a cruising speed of 16 knots. Two permanent magnet motors output 450kW power at 1180 rpm to drive the ship. The electric motor and propulsion control system are provided by Westcon. This battery powered propulsion system eliminates NOx and CO2 emissions, reducing noise and vibration.

The feathering position function of the system further minimizes drag and speed losses, thereby reducing the required propulsion power. The main propulsion system, as well as the bow and stern thrusters, are equipped with VACON ® Frequency converters are used to control speed, optimize power consumption, and control capabilities. In addition, the grid connected converter is a VACON that provides reliable power for the auxiliary distribution board ® Frequency converter. All frequency converters ensure safe and efficient power conversion of the battery pack.

Adequate lubrication

Converting the power generated by the electric motor into controlled propulsion in the most efficient way also helps to minimize energy consumption. Adequate lubrication is the key to efficient propulsion, which can only be achieved through precise control of pressure and temperature under all operating conditions.

The propulsion system is equipped with Danfoss's MBC5100 pressure switch, MBT 5250 temperature sensor, MBS 5150 pressure transmitter, and PVG 32 high-performance proportional valve, ensuring optimal lubrication of the propeller reduction gear and minimizing energy consumption.

The world's first floating power terminal

The local power grid capacity is insufficient to directly charge the "Fjord Future". The ship charges its batteries at PowerDock, a floating fiber optic dock with a charging capacity of 2.4 MWh: 1.2 MWh from the battery pack and 1.2 MWh from the power grid.

The power terminal can be charged throughout the day and is powered by the local power grid. The ship only needs 20 minutes to charge, during which the terminal will transmit 800 kWh of electricity. Westcon has equipped the power terminal with 2.4 MW VACON ® The frequency converter and its own control system ensure seamless integration of all components.

The "Future of the Fjord" vessel has taken the lead in achieving zero emissions targets, opening up a new development model for us. In the future, we will not only have modern equipment, but also usher in a vibrant world!